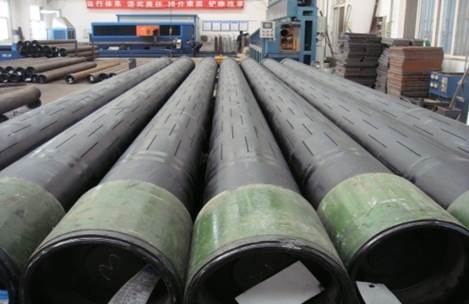

Darun has developed the most advanced slotting technology in the world, involving precision motion control, blade optimization and cutting robotics which allows us to provide an unmatched level of service quality and accuracy. In the past 6 years, Darun has produced approximately 4,100,000 meters of slotted liner and 900,000 meters of seamed liner for almost every major Oil & Gas company in the World.

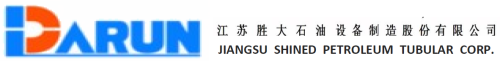

Our slotted liner offers the most complete and cost effective sand control method for SAGD and CSS operations. Using custom built, multi spindle slotting machines, Darun has the ability to provide variable slot densities that can be used to optimize inflow or outflow distributions along the horizontal length. Slot width is carefully calculated based on analysis of core particle size ranging from 0.010 inch to 0.250 inch.

Oil slotting pipe is the key part to protect from sand during oil mining. Oil slotting pipe can be classified into five types: bridge type oil slotting pipe, drilling slotting pipe, kerf slotting pipe, composted pipe, wire-wrapped slotting pipe. Oil slotted casing pipe is cut by specialized ultra-thin cutting disk and laser beam. There are many certain configurations kerfs with shape of longitudinal or helical straight line on oil slotted casing pipe.

Oil slotting pipe laser cutting machine adopts advanced technology, which can cut different type of oil slotting pipe. By means of focusing, high density and high-power laser beam working on sieve pipe, on the premise of exceeding a threshold value of laser power density, heat energy from working gas and laser beam’s chemical reaction is absorbed by material, thus causing a dramatic increase in the temperature of laser sport on the surface of the casing, partial melting or gasification of workpiece material to form a hole, then relative motion of the casing and laser beam can achieve casing cutting.

Advantages of Laser Processing for Oil Casing Tube:

1.High precision: positioning precision is 0.05mm, repeated positioning accuracy is 0.02mm.

2.Narrow kerf: laser beam can be focused to a tiny light-spot, so that focus place has high power density, material will be heated quickly to gasification degree and vaporized to hole. As the relative linear movement of beam and material, the continuous hole will generate narrow kerf. The cutting edge width is generally 0.1mm to 0.2mm.

3.Cutting surface is smooth: no burr in cutting surface, cutting surface roughness is controlled within Ra12.5.

4.High speed: cutting speed can reach 10m/min, the maximum positioning speed can reach 200m/min, which is faster then linear cutting.

5.Excellent cutting quality: non-touch cutting, cutting edge has small thermal effect, workpiece has small thermal deformation, avoid tuned-down edge, kerf needn’t twice processing.

6.No damage to workpiece: laser cutting head will not touch material surface, no scratch to workpiece.

7.Not depends on material hardness: laser can process steel plate, stainless steel, aluminum alloy plate, hard alloy. No matter how hard the material is, it can cut without deformation.

8.Good flexibility: Laser cutting has good flexibility, it can process different figures, it can cut pipe or other profiled material.